Company Introduction

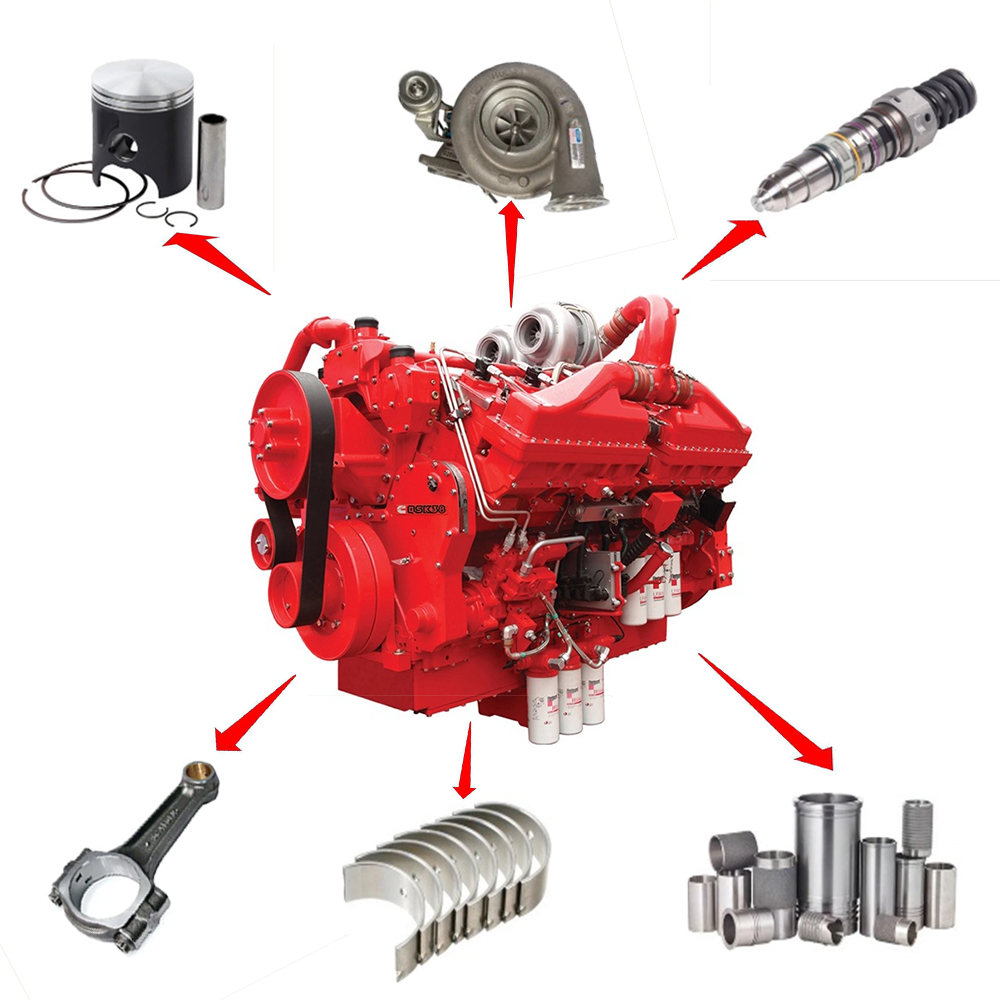

Raptors, the authorized dealer of Cummins (China), established in 2015 by Mr. Jordan Wang who worked in Cummins (China) for 8 years, Jordan had been responsible for mine market for 4 years during working in Cummins china, so we have big advantages for almost all genuine Cummins generators, engine assembly and spare parts, especially for NTA855, KTA19, KTA38, KTA50, QSK60, QSX15 etc...What is an oil cooler The function of the oil cooler is to cool the lubricating oil and keep the oil temperature within the normal working range. On a high-power reinforced engine, an oil cooler must be installed due to the large thermal load. When the engine is running, the lubricating capacity is reduced due to the thinning of the oil viscosity with increasing temperature. Therefore, some engines are equipped with oil coolers, whose function is to reduce the temperature of the oil and maintain a certain viscosity of the lubricating oil. The oil cooler is arranged in the circulating oil circuit of the lubrication system, and its working principle is the same as that of the radiator.

Types of Engine Oil Coolers 1) Air-cooled oil cooler The core of the air-cooled oil cooler is composed of many cooling pipes and cooling plates. When the car is running, the hot oil cooler core is cooled by the oncoming wind of the car. The air-cooled oil cooler requires good ventilation around it. It is difficult to ensure enough ventilation space on ordinary cars, and it is rarely used. Most of the coolers are used in racing cars, because the racing speed is high and the cooling air volume is large. 2) Water-cooled oil cooler The oil cooler is placed in the cooling water circuit, and the temperature of the cooling water is used to control the temperature of the lubricating oil. When the temperature of the lubricating oil is high, it is cooled by the cooling water, and when the engine is started, the heat is absorbed from the cooling water to rapidly increase the temperature of the lubricating oil. The oil cooler consists of an aluminum alloy cast casing, front cover, rear cover and copper core tube. In order to enhance cooling, heat sinks are installed on the outside of the tube. The cooling water flows outside the tube, the lubricating oil flows inside the tube, and the two exchange heat. There are also structures that allow oil to flow outside the tube and water to flow inside the tube.

Types of Engine Oil Coolers 1) Air-cooled oil cooler The core of the air-cooled oil cooler is composed of many cooling pipes and cooling plates. When the car is running, the hot oil cooler core is cooled by the oncoming wind of the car. The air-cooled oil cooler requires good ventilation around it. It is difficult to ensure enough ventilation space on ordinary cars, and it is rarely used. Most of the coolers are used in racing cars, because the racing speed is high and the cooling air volume is large. 2) Water-cooled oil cooler The oil cooler is placed in the cooling water circuit, and the temperature of the cooling water is used to control the temperature of the lubricating oil. When the temperature of the lubricating oil is high, it is cooled by the cooling water, and when the engine is started, the heat is absorbed from the cooling water to rapidly increase the temperature of the lubricating oil. The oil cooler consists of an aluminum alloy cast casing, front cover, rear cover and copper core tube. In order to enhance cooling, heat sinks are installed on the outside of the tube. The cooling water flows outside the tube, the lubricating oil flows inside the tube, and the two exchange heat. There are also structures that allow oil to flow outside the tube and water to flow inside the tube.Product Parameter